Streifeneder Group has a history of about a hundred years since its establishment and is one of the world's renowned suppliers of rehabilitation products such as prosthetics and orthotics. In Europe, its brand influence is comparable to that of Ossur and Ottobock, and is highly appreciated by many consumers. Streifeneder Group has several companies covering many fields of prosthetics and orthotics.

F. G. Streifeneder KG has orthopedic and rehabilitation technologies, and is also a medical supplies store.

Streifeneder Klinikwerkstätte München-Großhadern GmbH provides personal assistive devices and professional rehabilitation products for children, adults, and the elderly, and is committed to providing patient with long-term after-sales service for the repair, adjustment, and improvement of assistive devices.

Orthopädietechnik München Harlaching GmbH customizes orthotics for patients. Their team has recruited professional orthopedic experts and is committed to providing customized orthopedic services for patients.

Orthomedical GmbH Medical supply store offers a wide range of medical products, including prosthetic breast, insoles, orthotics, sports and fitness equipment, canes, hearing aids, and more. It also has experienced and well-trained experts to provide comprehensive advice and help find the right product for you.

Mödl Orthopädie-Technik GmbH Hospital workshop provides patients with projects, products, and services of various prosthetic, orthotic, and Pressure assistance.

ortho.production GmbH specializes in providing a platform for professionals to learn and exchange, offering practice oriented continuing education.

Profile

From the hernia belts of a travelling salesman to a global company with 700 employees: The passion for technical tinkering paired with the goal of really helping people move forward is a recurrent theme in our history. Craftsmanship and humanity – that’s Streifeneder.

The story of the Streifeneder Group:

1928 · Life-saving hernia belts and founding a company

It is hard to believe today – in the past, an inguinal hernia often meant a death sentence. Patients often did not live past the age of 50. This was what drove Friedrich Georg Streifeneder to develop and patent a hernia belt. At that time, his pre-cut hernia belts were delivered by bicycle to seamstresses in the village, where they were finished and later collected.

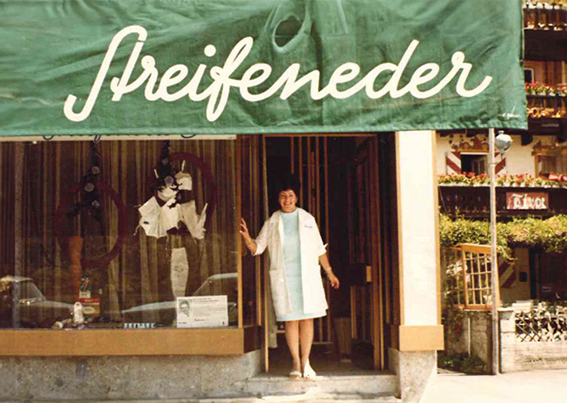

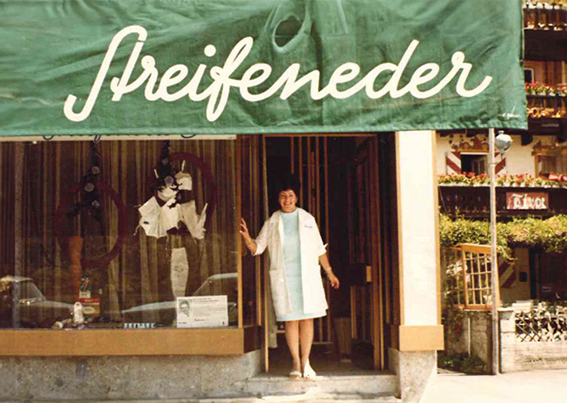

As a travelling salesman, Friedrich Georg Streifeneder sold the “hernia belt pads” throughout Germany, Austria and Switzerland and ultimately founded the company Streifeneder together with his wife Lilli. By the way, hernia belts are no longer made by Streifeneder, but they are still sold and fitted in their medical supply stores.

1945 · Post-war care

War invalids caused a rush to the orthopaedic workshops – the demand for prostheses was huge. At Streifeneder, the prostheses were precisely made to fit on copy milling machines originally intended for the production of figures of saints. This allowed countless prostheses to be produced in a short time and many people could be fitted with them, for example in the Bad Tölz hospital. Bernd Streifeneder, the son of Lilli and Friedrich Georg, was directly involved in care – he himself worked in the Bad Tölz workshop at the time.

By the way, many of the injured people treated by Streifeneder came from Finland and spoke excellent English – which greatly improved the English skills of the staff.

1968 · A real stroke of luck

The hit Streifylen was a chance discovery: Bernd Streifeneder was experimenting with packaging material from a plaster consignment that had aroused his interest. The white plastic sheet could be easily shaped to an orthosis. A sensation – until then, orthoses had to be cast in a laborious process. Streifylen has proven itself in orthopaedic technology to this day because it is so easy to work with.

1972 · The birth of rehabilitation technology

In the 1970s, the heart of German orthopaedic technology beat at Streifeneder: Murnau Hospital was looking for a provider and found what it was looking for in Streifeneder. Robert Streifeneder, then managing director, developed customised wheelchairs – an absolute novelty at the time compared to the bulky standard wheelchairs. Rehabilitation technology in Germany was born. To this day, this division has enjoyed great success.

1992 · A discovery and a big mistake

Shoe insoles made of soft foam that did not pinch: an invention by Bernd Streifeneder at the request of an orthopaedic specialist. His older patients really had a hard time with the hard insoles in their shoes. The new base material was a complete success and the soft foam inserts were well received.

Streifeneder, however, did not patent the inserts. From today’s perspective, this was a big mistake: Flexible foam inserts now account for a huge share of all insoles sold.

Living and working

In the post-war period, in addition to a great need for prosthetic specialists, there was also a large number of refugees to accommodate. Streifeneder had both jobs and accommodations, as a result of which the company was easily able to find enough employees.

Residential construction is still important at Streifeneder today; apartments are planned as part of every major construction project. A special microcosm: the headquarters in Rottmannstraße, whose apartments above the medical supply store were exclusively occupied by family members and employees from the very beginning.

The nest of orthopaedic technology

Training – a key topic at Streifeneder since 1945. After all, how do you get better new talent than by training them yourself? Many generations of prosthetic specialists from the Munich area learned their trade at Streifeneder.

With the ortho.production Academy, Streifeneder now offers further training for those who have already completed their training – incidentally, also for our competitors, because our philosophy was and still is: “Anyone can come to us!”

Failures and an important principle

Not everything went smoothly in the history of Streifeneder – with good luck and bad luck, minor and major wrong decisions – and failing to patent the flexible foam inserts is just one example. But the premise that “setbacks may be only so large that you survive them” still holds true today: a balance between risk and caution, courage without recklessness – these are the Streifeneder principles for good management.

Out into the world

Just do it – this also applies to exports at Streifeneder, for example. Early on, the company supplied countries that were too complicated for other companies. The employees at Streifeneder pragmatically familiarised themselves with the most difficult sets of regulations in order to send devices anywhere in the world.

Sometimes in a very personal way: For example, the bulk purchase of a royal family from the Middle East was delivered by Streifeneder directly to a private jet on the tarmac of Munich Airport. That the baggage compartment was already full at that time did not matter: after the first flight, the jet simply returned to Munich to pick up the devices.

Emmering and many new ideas

From 1993 onwards, the new premises in Emmering offered plenty of space for the growing company. Production, sales and services have been and are constantly being expanded; additional medical supply stores and workshops in southern Bavaria were added. To this day, Streifeneder is always coming up with something new – for orthopaedic technology and, above all, for the people who work with or use it.

Steady growth

Today, with over 700 employees, the Streifeneder Group is one of the largest regional employers in the Fürstenfeldbruck area. The establishment of the ortho.production Academy, the integration of the central insole production at the Emmering site and many new investments ensured constant, organic growth. This development can also be seen in the existing buildings of the company headquarters in Moosfeldstraße: hardly a year goes by without extensions, conversions or new construction.